The cannabis market in Colorado and across the United States is maturing fast, and so are expectations for packaging. Brands must balance product protection, compliance, and shelf impact while staying nimble with changing regulations and demand. That’s where flexible packaging shines for cannabis products. As Colorado’s only provider of both printed flexible packaging and pressure sensitive labels, CLP supports brands with FDA-compliant, GMP-certified materials, advanced flexographic printing, and fast turnarounds built for today’s competitive market.

Below are five key advantages of choosing Flexible Packaging for cannabis products.

1. Product Protection that Preserves Potency, Aroma, and Freshness

- High-barrier films protect against oxygen, moisture, light, and odor transfer, helping preserve terpenes, texture, and flavor.

- Custom laminations and heat-sealable structures create durable, tamper-evident, and leak-resistant formats.

- Engineered shelf life through film selection (e.g., UV-blocking or moisture-vapor control).

How this helps different formats:

- Flower

Odor containment and moisture control maintain aroma and integrity. - Edibles

Grease/oil resistance and oxygen barriers help preserve flavor and texture. - Vapes and accessories

Scratch-resistant films and sealable pouches reduce scuffing and contamination during transit.

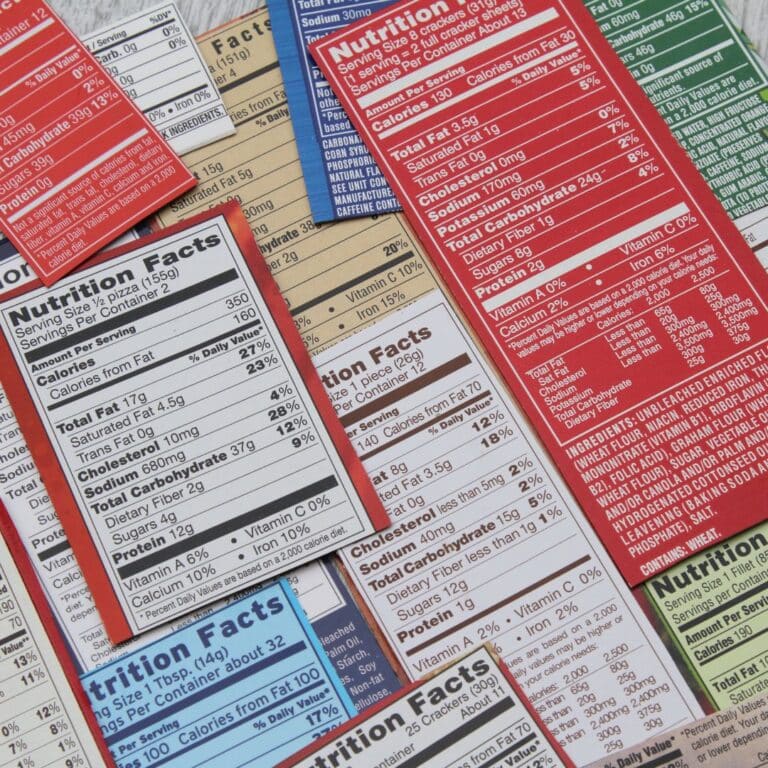

2. Compliance-ready Space and Print Clarity for Regulated Markets

Packaging rules vary by state, and Colorado’s requirements are particularly specific. Flexible formats offer:

- Ample real estate for warnings, universal symbols, dosage, and batch/lot coding without crowding the design.

- High-resolution graphics and readable microtext to keep mandatory copy crisp and legible.

- Tamper-evident and reclosable features to support safety and freshness.

- Compatibility with pressure sensitive labels for rapid updates as regulations change.

Tip: Regulations evolve. Always verify current cannabis packaging requirements in your operating states.

3. Brand Impact and Premium Shelf Presence

Flexible Packaging can be a canvas for brand-building:

- Vibrant, high-fidelity color with advanced flexographic printing (including reverse print and laminated print).

- Custom finishes such as matte, soft-touch, gloss, and spot varnish for tactile contrast and premium cues.

- Stand-up pouches that “billboard” on shelf and peg-display options for visibility in tight retail spaces.

- Support for short runs to test limited editions, strains, or seasonal SKUs without overcommitting inventory.

With CLP’s in-house prepress and design team, artwork is optimized for print, ensuring clean registration, consistent color, and fast approvals.

4. Efficiency Without Compromising Performance

- Less material by weight than most rigid options, which can reduce plastic consumption per unit.

- Lower freight weight and space efficiency mean fewer trucks, reduced fuel use, and lower emissions across Colorado and the United States.

- Right-sized packaging minimizes air and void fill, cutting waste and improving unboxing experience.

These gains add up, especially for multi-SKU cannabis portfolios where small improvements in each pouch or film roll scale significantly.

5. Cost control, Scalability, and Speed to Market

- Short and large production runs help you match supply to demand, ideal for strain drops, new product pilots, or multi-state launches.

- Fast turnarounds keep inventory agile: CLP typically delivers flexible packaging in 4 weeks or less and labels in 1 week or less.

- In-line efficiencies with flexography reduce per-unit cost at scale while maintaining quality.

- Metric repeat and re-register capabilities streamline versioning for different states or potencies.

For brands operating in Colorado and across the United States, these advantages help reduce risk, avoid obsolescence, and move quickly as regulations or market trends shift.

CLP pairs Flexible Packaging with pressure sensitive labels, enabling quick compliance updates, strain-specific versioning, and cohesive brand systems across films and pouches. With FDA-approved, GMP-certified materials, advanced UV flexo capabilities (up to 8 colors for labels), and expert prepress, your packaging can be both production-ready and retail-ready.

Since 2002, Colorado Label & Packaging (CLP) has been a leading provider of custom flexible packaging and pressure-sensitive labels in Denver, Colorado and throughout the U.S. Contact us today to learn how we can bring your vision to life.